Ready to Embrace Smarter Energy Management? Our Smart Power Quality Panels Lead to a Sustainable Future

When it comes to seizing the future of smarter energy management, look no further than ICD! Discover how our Smart Power Quality Panels are transforming the landscape towards an eco-friendly, high-efficiency tomorrow. Don’t miss out on the sustainable energy revolution – choose ICD today and unlock your pathway to a greener, smarter future!

HPFC - Hybrid Power Factor Correction Panel

Unleash Efficiency with HPFC – View Product to Slash Energy Costs

DPFC - Dynamic Power Factor Correction Panel

Stay Ahead of Fluctuating Demands with DPFC – Join Us to Boost Efficiency Instantly

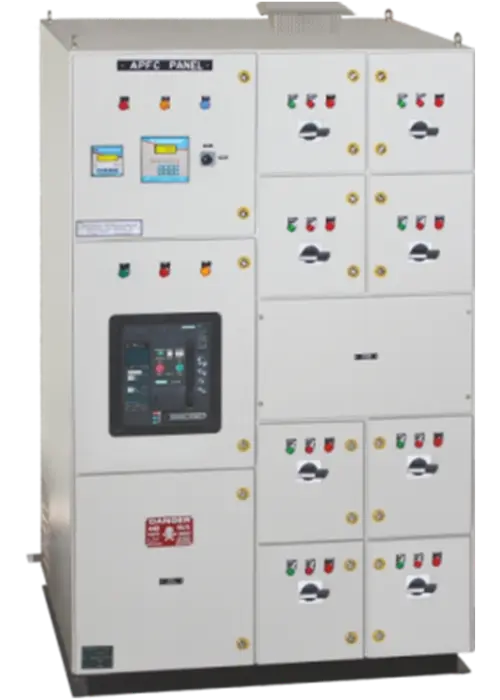

APFC - Automatic Power Factor Correction Panel

Simplify Energy Optimization with APFC – Contact for Hassle-Free Savings